Excellence in technology

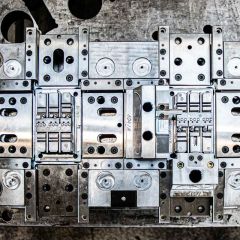

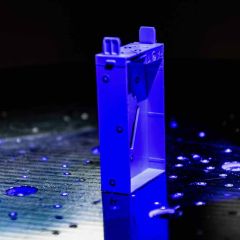

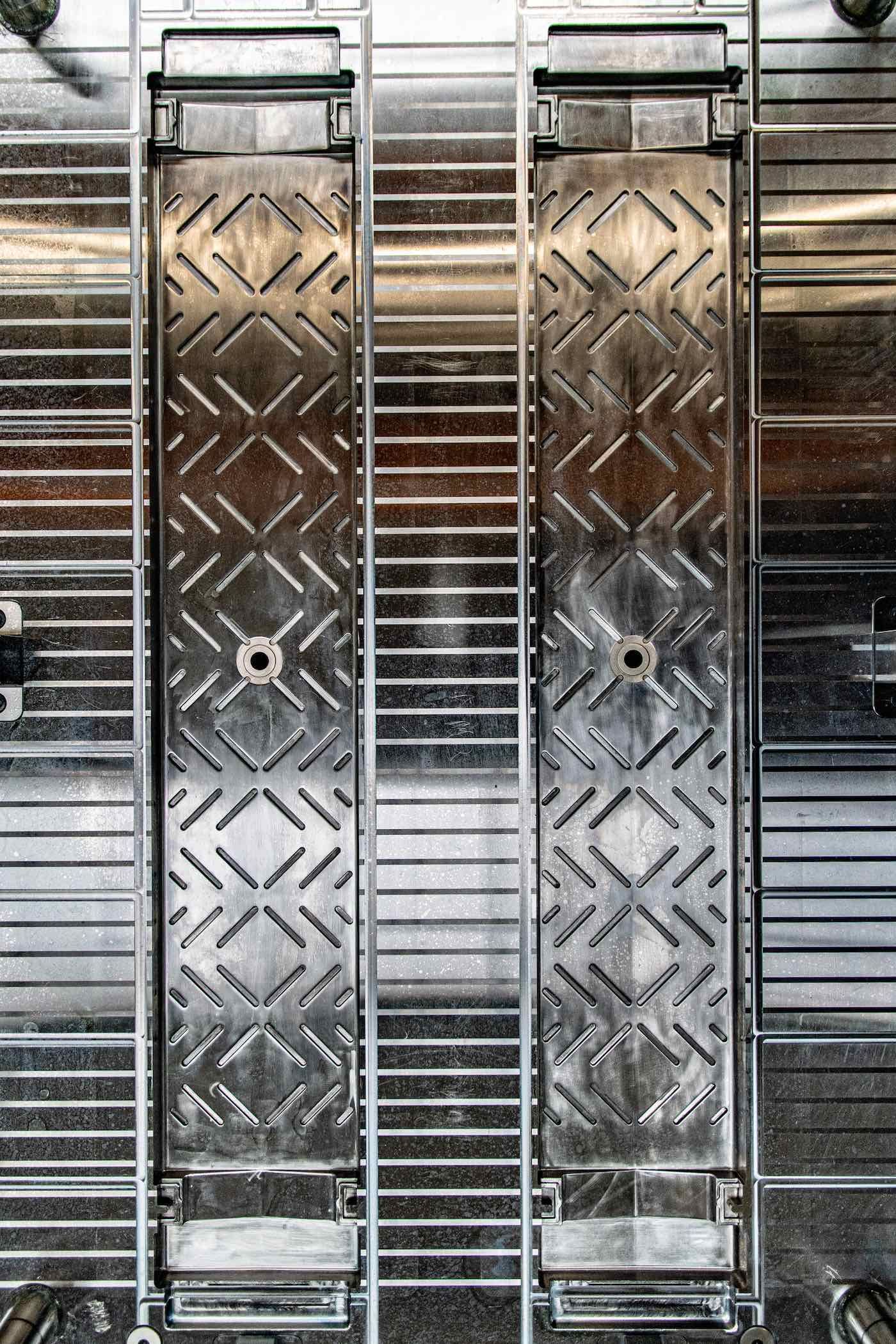

Injection Moulding & Tooling

Modern

solutions for industry

We are an experienced company with an established position on the market. We started our business in 1996.Thanks to well-considered management, and investing in the latest technological achievements, we have achieved the effect of ensuring continuous and sustainable development. Continuous improvement and expansion of our range of services has enabled us to achieve a stable position on the market.

Top quality

Through the use of modern measurement techniques and continuous monitoring of indicators, we are able to satisfy the most demanding customers

Complexity

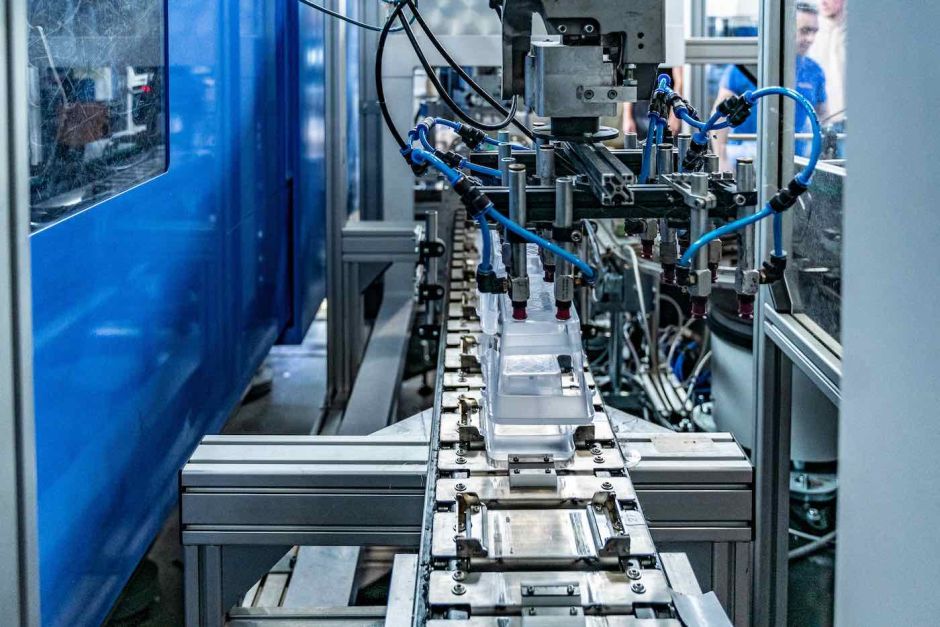

We are able to provide solutions related to the entire project life cycle from design to industrial production

Experience

We have staff with many years of experience. This enables us to provide a high level of service and support.

Environment

We invest in environmentally friendly solutions such as electric machinery and photovoltaic installation

Machine park

We have built a 600 m2 production hall where work is carried out on all-electric injection moulding machines

Let's talk and do the project

News

INTEMO na konferencji Tool Valley – innowacje w formach SLM

Dziś mieliśmy ogromną przyjemność uczestniczyć w konferencji „Forma w…

Jak INTEMO S.A. wspiera młodych w rozwoju kariery podczas IV Dnia Strefy

🎉 Jesteśmy na IV Dniu Strefy! Dziś spotykamy się z uczniami i stude…

A New Stage in INTEMO's Development

Another groundbreaking day in our company's history!

Today, the firs…

Opening of loading docks - 25.07.2025

We are pleased to inform you that on July 25, 2025, at 10:40 AM, the…

Plastpol 2025 behind us

Thank you for visiting us at PLASTPOL 2025!

We would like to exte…

Welcome to PLASTPOL 2025

INTEMO S.A. Hosts an International Delegation from the Tooling and Processing Industry

INTEMO S.A. Hosts an International Delegation from the Tooling and Pr…

INTEMO awarded by the Pomeranian Special Economic Zone

New warehouse

Green energy for Intemo S.A.

Our new magazine

Intemo's new development is a state-of-the-art warehouse with a height of 15 m and an area of 980 m², allowing for the storage of up to 2,546 pallets on mobile racks.

Two silos, 25 m high and 4.2 m in diameter, with two chambers of 148 m³ each, hold a total of 360 tonnes of plastic. The entire process is supported by the SAP system, which allows online tracking of goods.